The Adhesive Manufacturing Process at Gresbond by Kajaria

5

Feb 2026

A tile installation lasts only as long as the adhesive behind it. At Gresbond by Kajaria, adhesives are developed for real site conditions—not just lab results. These products are meant for homes, offices, bathrooms, kitchens, balconies, and outdoor areas where moisture, load, and daily use are part of the job. To understand what truly makes a difference, choosing the Best Tile Adhesives is critical for long-term performance.

Modern tile adhesives do much more than stick tiles. They hold weight, absorb small surface movements, resist water, and help tiles stay firm for years. When you understand how Gresbond adhesives are manufactured, choosing the right product becomes easier and smarter—for both professionals and homeowners.

This guide explains the adhesive manufacturing process at Gresbond by Kajaria in clear, easy language, and shows why these solutions perform better than traditional cement fixing.

Why the Manufacturing Process Matters

An adhesive performs well only if it is made well. At Gresbond, every stage—material selection, mixing, testing, and packing—is carefully controlled. Each step affects bonding strength, workability, setting time, and resistance to moisture and temperature changes.

When manufacturing is done right, common problems like loose tiles, hollow sounds, cracks, and tile pop-ups are greatly reduced. Tile adhesives and grouts are engineered products, not just cement mixed with sand. Their quality starts inside the factory.

The Complete Tile Adhesive Manufacturing Process at Gresbond by Kajaria

Step 1: Raw Material Selection

The process begins with choosing the right raw materials. Gresbond by Kajaria uses high-grade cement, refined sand, polymers, and performance additives. Each ingredient has a clear role—some improve bonding, some add flexibility, and others protect against moisture, which is why products like CX-1 tile adhesive deliver consistent performance on site.

Using consistent, quality materials ensures the adhesive works reliably on different surfaces and keeps tiles fixed for the long term.

Step 2: Precision Mixing & Formulation

Once selected, materials are mixed using automated systems that measure exact quantities. Proper mixing is critical. Even a small imbalance can affect site performance.

Accurate formulation ensures the adhesive spreads smoothly, grips tiles properly, and sets within the expected time. This is especially important for polymer-based tile adhesives, where consistency from bag to bag matters on large projects.

Step 3: Quality Control & Testing

Before packing, every batch goes through strict quality checks. Adhesives are tested for bonding strength, setting time, flexibility, and performance in dry and wet conditions. This is why products like VX-1 tile adhesive consistently meet demanding site standards.

These tests ensure the product works well in bathrooms, kitchens, high-traffic floors, and other demanding areas. This level of testing is what separates Gresbond adhesives from low-quality alternatives that often fail after installation.

Step 4: Automated Packaging

After approval, adhesives are packed using automated machines. This keeps the product clean and protects it from moisture and contamination. Machine packing also ensures accurate weight in every bag.

Special products like epoxy grouts and epoxy adhesives are packed with extra care so their performance remains intact until site use.

Step 5: Application-Focused Product Design

Gresbond adhesives are designed based on where they will be used. Floors, walls, large-format tiles, and wet areas all need different bonding properties. That’s why Gresbond offers specific solutions for each application instead of a one-product-fits-all approach.

Tools like the tile adhesive selector help users quickly choose the correct product for their site conditions.

Step 6: Installation Support & Right Tools

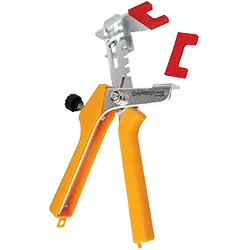

Manufacturing is only one part of performance. Correct installation tools also matter. Using systems like a tile leveling system keeps tiles aligned and evenly spaced, allowing the adhesive to perform as intended. Supporting tools such as a rubber mallet and application aids like TC-1 further improve accuracy during installation.

When the right adhesive is paired with the right tools, the finished tile work looks clean, even, and professional. Finishing products like KE-100 Glitter enhance the final appearance, while maintenance solutions such as marble cleaner help preserve the surface quality long after installation.

Step 7: Education Through Video & Demonstration

Gresbond also focuses on education. A dedicated manufacturing process video explains how materials are mixed, tested, and packed.

This helps contractors, architects, and homeowners clearly understand what goes into each bag of adhesive.

Step 8: From Factory to Site Performance

The goal of the adhesive manufacturing process at Gresbond by Kajaria is simple—long-lasting performance on site. Properly manufactured adhesives reduce tile failures, handle surface movement, resist moisture, and extend the life of the installation. This is why solutions such as EX-5 tile adhesive and LX-7 tile adhesive are trusted for demanding applications.

That’s also why modern solutions like tile adhesive chemicals perform far better than traditional cement, especially in areas where durability truly matters. For finishing and joint protection, products like premium unsanded grout and supporting systems such as KGA-01 help complete installations that last longer and perform consistently.

FAQs

1. What is the adhesive manufacturing process at Gresbond by Kajaria?

It includes raw material selection, precision mixing, quality testing, and secure packaging.

2. Why are Gresbond tile adhesives better than cement fixing?

They offer stronger bonding, better moisture resistance, and improved flexibility.

3. What role do polymers play in Gresbond adhesives?

They increase bonding strength, flexibility, and help reduce cracks over time.

4. Are all tile adhesives made the same way?

No. Gresbond formulates different products based on tile size, surface, and usage area.

5. How is adhesive quality checked?

Each batch is tested for bonding strength, setting time, and wet-area performance.

6. Why is automation important in manufacturing?

It ensures accurate mixing, consistent quality, and clean production.

7. Can poor manufacturing cause tile failure?

Yes. Weak formulation and poor quality control often lead to loose or cracked tiles.

8. Do epoxy adhesives need special handling?

Yes. They require controlled mixing and careful packaging.

9. How does manufacturing affect ease of application?

Correct formulation ensures smooth spreading and predictable setting time.

10. Why should users understand how adhesives are made?

It helps them choose the right product and avoid long-term installation problems.