PUA-100 - Highly Flexible, Two-Component Polyurethane Adhesive For Diverse Surfaces Like Metal, Plywood & Drywalls

PUA-100

Highly Flexible, Two-Component Polyurethane Adhesive For Diverse Surfaces Like Metal, Plywood & Drywalls

PRODUCT DESCRIPTION

GRESBOND PUA-100 is a high-performance, two-component polyurethane thinset adhesive designed for superior bonding of tiles and stone on both interior and exterior floors and walls. Engineered for exceptional flexibility, it is ideal for a wide range of substrates, including metal, plywood, and drywall. This multipurpose adhesive ensures strong and durable adhesion, making it the perfect solution for challenging installations.

×

Features and Advantages

Two components just mix and use.

Long open time - suitable for large format & external condition too.

Water, freezing, thermal shock resistant.

Sustains heat aging - Ideal for external & high-temperature applications.

Highly flexible adhesive - sustains heavy vibrations.

Chemical resistant & resistance to solvents, alkalis & oils.

Suitable for multiple substrates including metals, drywalls & plywoods.

Suitable for fixing all tiles/stones including composites, artificial stones, metal & glass tiles.

Application

Apply adhesive to the substrate with the flat side of the trowel.

Comb on additional adhesive with the notched side.

Use the proper sized notched trowel to ensure full bedding of the tile.

Tiles must be fixed within 60 minutes of adhesive being applied, depending on atmospheric conditions.

Check the adhesive ribs periodically and if a skin has formed, remove the dried adhesive and apply fresh adhesive.

Press the tiles firmly into position with a slight twisting action, checking periodically that good contact is maintained with the back of each tile and gently tap using a rubber mallet to embed tile and adjust level.

Leave no voids behind tiles.

For large size tiles or irregular surfaces, adhesive can additionally be buttered on the back of the tiles to ensure full adhesive contact.

Use suitable support along with adhesive for fixing tiles on vertical surfaces.

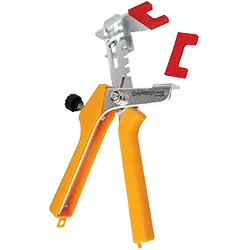

Leave adequate joints between individual wall and floor tiles using GRESBOND spacers.

The joint width shall be as per the recommendation of the architect/engineer. Provide joints (spaces) on the periphery of the area without allowing the tile/stone to be bound by the peripheral area.

Fill the resulting grout joints with flexible materials like GRESBOND epoxy range/suitable silicon or acrylic sealants. Tap the back of each tile using a rubber mallet to embed tile and adjust level.

Clean off surplus adhesive from the tile face and between joints.

Clean tools and tile work with water or suitable solvent while adhesive is fresh. Once cured, the adhesive can only be removed by mechanical means.

Area of Use

Material to be Fixed: All types of tiles, glass mosaic tiles, large format tiles, precast terrazzo, all-natural stones, large thin/slim tiles, composites/artificial/nano/engineered stone, metal & glass tiles.

On Surface / Substrate: Cement-based surfaces (screeds, plaster, concrete), metal surfaces (iron, steel, copper, aluminium etc.), Epoxy/PU based substrate, drywall surfaces (like gypsum/bison/fibre/cement board), existing tiles & stones, plywood, MDF & wood derivative, rubber, PVC etc.

Area of Application: Floor and walls, internal & external area, window/door frame, vibrational area, kitchens, balconies, roofs, domes, terraces, domestic applications, commercial applications, industrial.

For all exterior tile/stone fixing and drywall tile installations, please consult our Technical Team.

APPLICATION

APPLICATION

INSTRUCTIONS

Surface Preparation

The substrate must be levelled, cured, undamaged, compact, rigid, resistant, dry and free from any debonding agents and from damp rising.

All surfaces must be plumb and true to within 6 mm in 10 ft (3m).

Dry, dusty surfaces should be dampened with water & excess water should be swept off.

New concrete slabs shall be damp cured and 28 days old before application which will reduce the shrinkage from tile fixing surface.

Rust on iron surfaces must be removed by sandblasting.

Expansion joints are to be provided & filled with suitable sealant.

Don't cover expansion joints with thin set tile adhesive/tile.

Mixing

The two components of GRESBOND PUA-100 are supplied in ready-to-mix bucket.

Pour the part B into part A and mix well until a uniform white paste is obtained.

Mix with a suitable mechanical stirrer or slow-speed drills (50-100 rpm) until a lump-free homogeneous paste is obtained.

Always mix the required quantity, which can be consumed within pot life.

Leave the mixture for 5 minutes before use.

The ratio of the part A and part B is fixed, and any modification and/or inappropriate ratio could cause incorrect hardening of the product.

Properties

Working

Properties

Technical Information | Application Properties

| Testing Properties | Test Results |

|---|---|

| Component Appearance | Part A (Base): White Paste | Part B (Hardener): Liquid |

| Mixing Ratio (Part A: Part B) | Part A: 4-4.7 kg & Part B: 0.300 kg (Part A: Part B = 100:15.5 by weight) |

| Mixed Material Appearance | Off White Paste Consistency |

| Mixed Density | 1.65 ± 0.1 kg/litre |

| Open Time | Min. 60 minutes |

| Adjustability | Min. 60 minutes |

| Pot Life | Min. 60 minutes |

| Sag/Slip | ≤0.5mm |

| Application Temperature (substrates and materials) | 10°C to 40°C |

| Resistance to Temperature | -40°C to +100°C |

| Setting / Trafficable / Grouting Time | 24 hours |

| Interval before Normal Use | 3 days (7 days for heavy-duty traffic) |

Performance Properties (as per ISO 13007 and EN 12004 – R2T)

| Test | Requirement | Result |

|---|---|---|

| Initial shear adhesion strength | ≥2.0 N/mm² | ≥5.0 N/mm² |

| Shear adhesion strength after water immersion | ≥2.0 N/mm² | ≥6.0 N/mm² |

| Shear adhesion strength after thermal shock | ≥2.0 N/mm² | ≥5.0 N/mm² |

| Tensile adhesion - Open time (at 60 min) | ≥1.0 N/mm² | ≥1.5 N/mm² |

| Slip resistance (T) | ≤0.5 mm | ≤0.3 mm |

Performance Properties (as per IS 15477:2019 – Type 5 'T S2')

| Test | Requirement | Result |

|---|---|---|

| Tensile adhesion (dry, 28 days) | ≥2.0 N/mm² | ≥2.5 N/mm² |

| Tensile adhesion (wet) | – | ≥1.5 N/mm² |

| Shear adhesion (dry) | ≥6.0 N/mm² | ≥7.0 N/mm² |

| Shear adhesion (wet) | – | ≥6.0 N/mm² |

| Shear adhesion (heat aging) | ≥3.0 N/mm² | ≥6.0 N/mm² |

| Deformability (S2) | ≥5.0 mm | ≥10.0 mm |

| Slip resistance (T) | ≤0.5 mm | ≤0.3 mm |

Note:

Test results are indicative as per testing method specified in standard.

Test results may vary as per substrate, site condition & testing machine etc.

Actual field performance will depend on installation methods and site conditions.

Grouting

Grouting should be carried out after 24 hours of tiling. Use the appropriate grouting material from the GRESBOND range of cementitious and epoxy grouts.

Safety Precautions

Keep out of reach of children. Wear suitable protective clothing, gloves and eye/face protection. After contact with skin, wash immediately with plenty of clean water. In case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice. Limited to professional use only. For more details, please refer to the relevant Material Safety Data Sheet, available on request.

Disclaimer: While the company guarantees its products against defective materials, the use and application of these products are made without guarantee since the conditions of their application are beyond its control. It is recommended to verify with the company that the product is suitable for the intended use, and that this data sheet version is the latest one. The company may modify it without prior notice. Technical characteristics are listed for guidance only. For more information, please contact the company office in your location.

Coverage

- 20-25 sq. ft/5kg pack-1.5 mm bed thickness (using 3 mm x 3 mm notch).

- 10-12 sq. ft/5kg pack - 3 mm bed thickness (using 6 mm x 6 mm notch).

*Coverage will vary depending on trowel notch size, type, size of tile and substrate smoothness and evenness.

Precautions

- Do not use on damp surfaces or where there is a risk of rising damp.

- Packs are pre-measured, therefore mixing errors are impossible. For partial mixing, weigh the two parts precisely.

- Any modification and/or inappropriate ratio could cause incorrect hardening of the product.

- Protect against direct rain/foot traffic for at least 12 hours.

- Tiles/stones should not be installed directly on expansion joints.

- Leave an appropriate gap between the tile & fill gaps with GRESBOND tile grout.

- The designer/applicator must evaluate the use of an additional mechanical fastening system for extra security for more than 3 m height (such as steel hooks fastened to the substrate).

LIMITATIONS

- Don't use in contact with polystyrene or on substrates which are not fully cured and subject to moisture rising.

- Do not use GRESBOND PUA-100 to bond transparent glass materials.

- Adhesives for ceramic tile, bricks and stone are not designed as replacements for waterproof coating.

- Use suitable water-proofing coating before tiling for wet area.