CX-1 - Polymer Tiles adhesive for concrete Floor

CX-1 for Ceramic Floor Tiles

Premium Tile Adhesive for Ceramic Floor Tiles

product Description

CX-1 is a polymer-based tile adhesive specifically formulated for fixing ceramic tiles and small format natural stone, clay tiles, terracotta and quarry tiles of regular size. It is suitable for both vertical and horizontal surfaces, over the cementitious substrate for indoor application, in dry as well as wet areas. Easy to use with just water mixing, CX-1 is perfect for dry areas and occasional moisture environments like bathrooms and kitchens. Choose CX-1 for exceptional bond strength, flexibility, fast curing, and user-friendly application.

×

Key Features And Benefits

-

Single-component, easy to use: Simply add water for a ready-mixed solution.

-

Interior applications: Ideal for use on interior floors and walls.

-

Economical: Cost-effective solution for tile installation.

-

Versatile: Bonds to various substrates including concrete, concrete masonry, and cement-based surfaces.

-

High-performance: Meets international classifications EN / ISO C1T and IS 15477:2019 – Type 1T.

Suitable Substrates

Application

Method

Method of Application

Remove all Dust, Water, Oil & Sealers from Surface/ Substrate

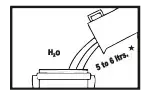

Add 5 to 6 * Itrs water/Admix in to empty bucket

Add 20 Kg CX-1 Thin Set Adhesive in to water and mix it till attains Uniform Paste

Slake the Material for 5 to 10 minutes

Again Mix the material then take the material on notch trowel

Use flat side of the trowel and spread the adhesive uniformly

Comb the adhesive with the help of Notch trowel

Spread the material backside of the tile also (If tile size is More than 12X12)

Press the tiles firmly into position by Twisting Action

Press the tile gently with help of Wooden Hammer to make uniform tile surface

Clean the Tile surface with wet Cloth

For Foot Traffic wait up to 24 Hrs

After 24 Hrs you can do the grouting

reliable

Technical Data

(Type-1)

| Property | Value |

|---|---|

| Density | 1.79 kg / litre approx. |

| Pot Life | 1.5 hrs approx. |

| Open Time | 22 minutes Approx. |

| Adjustability | 21 minutes Approx. |

| Setting Time | Approx. 1 Day |

| Full Strength | Approx. 14 Days |

| Tensile Strength | > 1.20 N/mm² |

| Shear Strength | > 1.00 N/mm² |

Coverage

Approximately 55-60 square feet per 20 kg pack, using a 1/4′′ x 1/4′′ (6mm x 6mm) square notched trowel for a 3mm bed. Approx. 1.2 kg/ m2 per mm of thickness. Coverage will vary depending on several factors including trowel notch size, tile type and size, and substrate smoothness.

data

IS Data

| Property: Test method | Requirement | Typical Values |

|---|---|---|

| Test method | ||

| Dry Condition – Annex A (Clause 5.1) | Minimum 0.50 N/mm² | 0.60-0.70 N/mm² |

| Shear Adhesion | ||

| Dry Condition – Annex B (Clause 5.2) | Minimum 1.00 N/mm² | 1.10-1.20 N/mm² |

| Slip Resistance | ||

| Slip Resistance – Annex E (Clause 5.5) | ≤0.50 mm | 0.25-0.35 mm |

Disclaimer: This technical data sheet is provided for informational purposes only. The information is based on our technical knowledge and experience. Due to variations in field conditions, we recommend conducting preliminary tests to ensure product suitability for your specific application.

Installation

Installation

Instructions

Surface Preparation

-

All surfaces must be between 40°F (4°C) and 104°F (40°C), structurally sound, clean, and free of dirt, oil, grease, loose paint, laitance, concrete sealers, or curing compounds.

-

Ensure the surface is plumb and level within 1⁄4 inch (6mm) over 10 feet (3 meters).

-

Smooth rough or uneven concrete surfaces with a screed or plaster material to achieve a wood float finish (or better).

-

Dampen dry, dusty concrete slabs or masonry and remove excess water before installation. New concrete slabs must be damp cured and at least 28 days old before application.

-

Incorporate expansion joints through the tile work to match any construction or expansion joints in the substrate. Do not cover expansion joints with mortar.

-

Gresbond EA-100 is recommended for tile or stone installations on plywood and wood substrates.

Mixing

-

Pour clean, potable water into a clean mixing bowl.

-

Add CX-1 powder to the water (approximately 5 - 5.5 liters of water per 20 kg of powder).

-

Mix by hand or with a slow-speed mixer until a smooth, trowelable consistency is achieved.

-

Allow the adhesive to slake for 5 minutes.

-

Adjust consistency if necessary.

-

Remix before applying with the proper sized notched trowel.

-

For large format tile or stone installations on exterior surfaces, contact Gresbond technical services.

Application

-

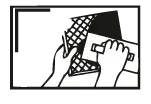

Apply adhesive to the substrate with the flat side of the trowel, pressing firmly to ensure good contact.

-

Use the proper sized notched trowel to ensure full bedding of the tile.

-

Comb additional adhesive onto the substrate with the notched side of the trowel. Use the appropriate trowel size to ensure full coverage of the tile back. Spread only as much adhesive as can be covered with tile within 10 minutes.

-

Back-butter large format tiles (greater than 12” x 12” or 300mm x 300mm) to provide full bedding and support.

-

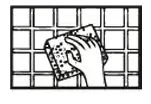

Place tiles into the wet, sticky adhesive and tap them in using a beating block and rubber mallet to embed the tile and adjust the level.

-

Periodically remove a tile to check for complete adhesive coverage by inspecting the amount of adhesive transferred onto the back of the tile.

-

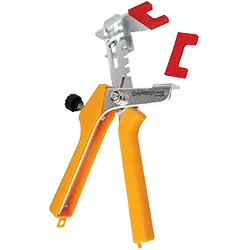

Use spacers to create grout joints between tiles/stones. The joint width should follow the architect's or engineer's recommendations. Remove spacers once the adhesive has set firmly.

-

If the adhesive skins over (loses tack), remove it and replace it with fresh adhesive.

-

Apply adhesive to the substrate with the flat side of the trowel.

-

Tiles must be fixed within 10-15 minutes of adhesive being applied, depending on the porosity of the surface and atmospheric conditions.

-

Leave no voids behind tiles.

-

Use suitable support along with adhesive for fixing tiles on vertical surfaces.

-

Leave adequate joints between individual wall and floor tiles using spacers. The joint width shall be as per the recommendation of architect / engineer.

-

Clean off surplus adhesive from the tile face and between joints.

-

Clean tools and tile work with water while adhesive is fresh.

Precautions & Note

-

Always add powder to water.

-

Do not add excess water than recommended.

-

Never add sand & cement at site.

-

Do not use on wet screed. Surface must be fully cured.

-

Do not use the adhesive to correct surface irregularities greater than 12 mm.

-

Protect from direct rainfall/ foot traffic for at least 24 hours.

-

Leave gap between the tile & fill gaps with Gresbond tile grout.

-

Designer/ applicator must evaluate the use of an additional mechanical fastening system for extra security for more than 3m height (such as steel hooks fastened to the substrate).

Limitation

-

Do not apply directly to gypsum plaster or boards, fibre cement boards or other drywall partitions, plywood, chipboard, particleboard, decorative laminates or resilient flooring, metal, plastic, deformable surfaces or subject to vibrations. Use Gresbond EA-100 as per application.

-

Adhesives for ceramic tile, bricks and stone are not designed as replacements for waterproof coating. Use waterproofing coating before tiling for wet area.

-

Do not use for fixing artificial/ nano/ engineered stone/ composites/ metal tile. Use Gresbond EA-100 for the same.

Grouting

-

Begin grouting after a minimum curing time of 24 hours at 70°F (21°C). Use Gresbond's KE-100 series epoxy grout or unsanded grout mixed with KGA-100 Grout Admix.

-

maximum stain resistance on interior spacer joints, use KE-100 Stain - resistant Grout.

Frequently Asked Questions

What is CX1 Tile Adhesive?

CX1 Tile Adhesive, a premium polymer-modified, cement-based adhesive, is your reliable partner for bonding ceramic and concrete floor tiles. It ensures a strong bond, flexibility, resistance to water and temperature changes, and durability, providing peace of mind for your tiling projects.

What is the density of CX1 Tile Adhesive Paste?

It is designed to be user-friendly, making it easy to spread and work with. It provides strong adhesion for years, ensuring your tiling projects are hassle-free.

How do you mix CX1 Tile Adhesive?

Mix CX1 Tile Adhesive by adding the powder to water in the recommended ratio and stirring until a smooth, lump-free paste is formed. For large batches, use a mechanical mixer to ensure consistency.

What makes CX-1 Tile Adhesive different from other cement-based adhesives?

Gresbond offers comprehensive solutions for walls, floors, and roofs for residential and commercial tiling projects. Whether you're renovating your home or working on a large-scale commercial development, Gresbond products, including ceramic, porcelain, natural stone, glass, and mosaic tiles, are designed to meet your tiling needs.

Is CX-1 Tile Adhesive a glue or a cement-based bonding agent?

It is a grey-colored polymer-modified cement-based bonding agent that acts as a strong adhesive, providing the benefits of both traditional cement and modern polymer-enhanced glues.

What is the best way to apply CX-1 Tile Adhesive for optimal results?

Mix using an electric chemical mixer and make a lump-free paste. Use a notched trowel to ensure an even thickness and proper coverage. Apply one coating on the surface and one coating on the tiles. Press the tiles firmly into the adhesive and adjust to maintain alignment and spacing.